Method Article

Evaluating the Effects of Different Polishing Methods on Color Stability of Dental Restorations in Pediatric Dentistry

In This Article

Summary

Here, we evaluated the impact of various polishing methods on the color stability of compomer and composite resin restorations used in anterior restorations within pediatric dentistry. This study highlights the significance of selecting appropriate polishing methods to enhance the color stability of compomer and composite resin restorations in pediatric dentistry.

Abstract

The aim of this study was to evaluate the impact of various polishing methods on the color stability of compomer and composite resin restorations used in anterior restorations within pediatric dentistry. One hundred and twenty disc-shaped specimens (8 mm diameter x 4 mm thickness) were prepared from A2 shade compomer and nanohybrid composite resin to assess color stability in four different polishing systems. Sixty specimens from each material were randomly distributed into five groups (n = 12) according to the polishing method used. Group 1: four-step aluminum oxide discs, Group 2: aluminum oxide discs and rubber kit, Group 3: aluminum oxide discs and felt discs, Group 4: aluminum oxide discs and spiral wheels, and Group 5: no polishing.

The specimens were immersed in cherry juice solution for 7 days. The color changes (ΔE) for all materials were assessed using a spectrophotometer at baseline and after 7 days of staining. The collected data were analyzed with the Shapiro-Wilk test, along with the Mann-Whitney U test for comparing two independent groups and the Kruskal-Wallis test for comparing three or more independent groups. Post hoc Bonferroni Corrections were applied to identify the groups causing the differences.

As a result of the analyses, statistically significant differences were determined between the staining measurements of the compomer and composite materials across the groups (p < 0.05). The highest level of discoloration for the compomer was in the control group. In conclusion, the selected polishing method influences the degree of discoloration in the compomer groups. In the composite group, polishing methods showed variable effects. Differences were found between the compomer and composite groups. Understanding these effects is crucial for maintaining the esthetic longevity of restorations in young patients.

Introduction

Physical appearance has become a significant concern in social perception and interaction. Social media promote an idealized look as the only acceptable standard, negatively affecting children and young adults1. Consequently, aesthetics has become one of the most crucial factors for people seeking dental treatments2. Numerous tooth-colored restorative materials have been developed to meet the increasing demand for aesthetics3. Resin composites, with their improvements in mechanical properties and formulations, and compomers (polyacid-modified resin composites) with their additional fluoride-releasing feature, are among the most commonly used tooth-colored restorative materials, especially in pediatric dentistry4.

Color stability is one of the most essential requirements for clinical success in tooth-colored restorative materials. Discoloration of these aesthetic materials over a period of time may occur with intrinsic and extrinsic factors5. Extrinsic factors of discoloration include smoking, poor oral hygiene, and consuming colorful meals and beverages, which can stain surfaces of the restorative materials due to the adhesion or penetration of colorants from external sources6. Intrinsic factors include the chemical structure of the restorative material itself, such as the resin matrix's composition and the interaction between the matrix and fillers. Dental practitioners may reduce this kind of discoloration by ensuring adequate polymerization and employing appropriate finishing and polishing techniques7.

Proper finishing and polishing are required to smooth the surface and remove excess material to improve the aesthetics and durability of restorative materials by eliminating the superficial resin layer that prevents polymerization when in contact with oxygen8. Numerous instruments like carbide and diamond burs, abrasive disks, impregnated rubber cubs, strips, and pastes have been designed in the field of dentistry to finish and polish the tooth-colored restorative material9. These instruments vary according to the flexibility of the finishing material, the hardness of the abrasive, the grain size, and the instrument application methods. Deciding the more appropriate finishing and polishing instrument depends on the shape and size, hardness of the filler material, and the proportion of the material in the overall composition10. According to Paravina et al.11, if the polishing material's particle size is smaller than the polished restorative material's particle size, a better restorative material surface will be achieved.

Although there have been several studies investigating the effectiveness of a polishing system on the surface roughness and color stability of tooth colored restorative materials, most of the studies evaluated composite material1,2,3,6,8,9,11. The literature includes a limited number of studies exploring the impact of various finishing and polishing systems on the color change of tooth-colored restorative materials commonly used in pediatric dentistry12. This present study aimed to evaluate the impact of various polishing methods on the color stability of compomer and composite resin restorations.

Protocol

To investigate the effect of polishing systems on the discoloration of composite and compomer resins, two commercial A2 shade restorative materials were tested in this study: compomer and nanohybrid composite resin. The list of resin restorations used is provided in the Table of Materials.

1. Specimen preparation

- Produce a total of 120 discs, with 60 discs made from each of the composite resin and compomer materials.

- Place the restorative materials into a silicone mold with an 8 mm diameter and 4 mm thickness.

- Before curing, press the materials between 1 mm glass plates with Mylar strips to match the mold's thickness. Use these glass plates to ensure that the specimens have flat, smooth surfaces, reducing the likelihood of variations in color measurements.

NOTE: Maintain consistency by using A2 shade for all materials. - Cure the restorative materials from one side with a light-emitting diode light cure for 20 s with an intensity of 1.470 mW/cm², following the manufacturer's instructions. Have a single operator prepare all the specimens.

- Randomly assign the discs of each restorative material to one of five polishing subgroups, with each subgroup consisting of 12 discs (Figure 1). Perform the power analysis to determine the minimum required sample size (power = 0.95, α = 0.05, β = 0.05).

- Finish the specimens in groups 1.1 and 2.1 (Figure 1) using a series of four-step aluminum oxide discs (Al discs) for 20 s each.

- Finish the specimens in groups 1.2 and 2.2 (Figure 1) with a one-step polishing rubber kit for 20 s at low pressure after first polishing them with Al discs using the same procedure.

- For groups 1.3 and 2.3 (Figure 1), finish the specimens with Al discs and one-step polishing felt discs for 20 s each. Subject the felt discs to continuous water irrigation.

- In groups 1.4 and 2.4 (Figure 1), perform the same disc application as in the other groups, then apply two-step spiral wheels for 20 s.

- In groups 1.5 and 2.5 (Figure 1), do not perform any finishing or polishing procedures.

- After finishing, store all prepared specimens in distilled water at 37 °C for 24 h to allow for rehydration and complete polymerization.

- Number each sample before conducting baseline color measurements.

- Use a spectrophotometer to evaluate the baseline color measurements of all groups, following the Commission Internationale d'Eclairage Lab* (CIELab) coordinates relative to a standard illuminant.

- Use a white background for the initial color measurements.

- Calibrate the spectrophotometer before each measurement following the manufacturer's instructions.

- Take color measurements 3x for each specimen to ensure accuracy.

Figure 1: Distribution of the study groups. Please click here to view a larger version of this figure.

2. Staining process

- To compare the ability of restorative materials and polishing techniques to resist discoloration, store the prepared discs in commercially available cherry juice. Incubate all samples at 37 °C for 7 days, refreshing the juice daily.

- At the end of the experimental period, thoroughly rinse the discs with distilled water and dry them with tissue paper before conducting color measurements.

- Apply the same procedure used for the initial color measurements using the referenced spectrophotometer.

3. Color difference measurements

- For color difference determination (ΔE), calculate the average values of ΔL, Δa, and Δb for each specimen. Use the following equation to calculate color variation13:

ΔE = [(ΔL*)2+(Δa*)2+(Δb*)2]1/2

Where L* represents the lightness of color, ranging from 0 (black) to 100 (white). The a* value indicates the position on the green-red axis, with positive a* values indicating red and negative a* values indicating green. The b* value represents the blue-yellow axis, where positive b* values indicate yellow and negative b* values indicate blue. - Based on previous studies1,11,13, consider a noticeable color change with a ΔE value ≥ 1 to be acceptable, provided it does not exceed ΔE = 3.3.

- Record color measurements for the experimental groups immersed in cherry juice.

4. Statistical analysis

- Provide descriptive statistics (mean, standard deviation, median, minimum, and maximum).

- Use the Shapiro-Wilk test to check the assumption of normal distribution.

- In cases where the normality assumption is not met, use the Mann-Whitney U test for comparing two independent groups, and use the Kruskal-Wallis test for comparing three or more independent groups.

- Apply post hoc Bonferroni Corrections to identify the groups that caused the differences.

- Use statistical analysis software to conduct the analyses.

Results

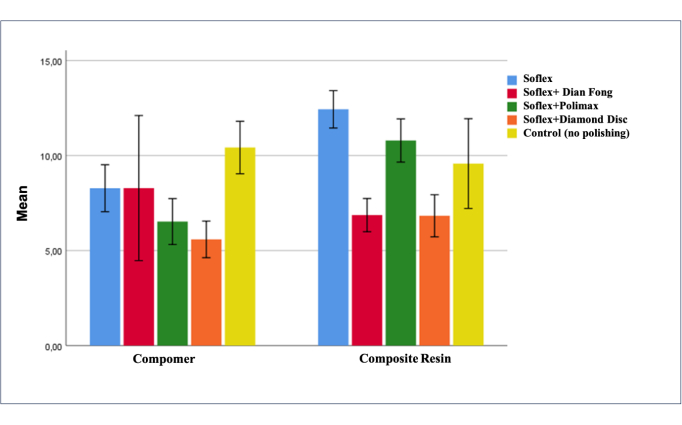

The mean, minimum, and maximum color values obtained from the measurements are presented in Table 1. Statistically significant differences in discoloration were observed among the groups of compomer and composite materials (p < 0.05).

| Compomer | Composite Resin | Compomer- Composite Resin | |||

| Min.-Max. | Mean±SD. | Min.-Max. | Mean±SD. | p | |

| (Median) | (Median) | ||||

| Four-step aluminum oxide polishing discs | 4.29-10.85 | 8.28±1.94 (8.44) | 8.95-14.5 | 12.44±1.55 (12.74) | <0.001* |

| Four-step aluminum oxide polishing discs+ polishing rubber | 3.01-26.19 | 8.29±6.01 (7.44) | 3.94-8.91 | 6.87±1.37 (7.09) | 0.59 |

| Four-step aluminum oxide polishing discs+ felt disc | 4.81-10.25 | 6.53±1.9 (5.74) | 8.45-14.23 | 10.79±1.79 (10.25) | <0.001* |

| Four-step aluminum oxide polishing discs + Spiral Wheels | 4.04-8.75 | 5.59±1.52 (5.32) | 4.67-9.68 | 6.83±1.75 (6.93) | 0.06 |

| Control | 8.1-15.33 | 10.42±2.17 (9.92) | 5.24-17.32 | 9.58±3.72 (8.67) | 0.266 |

| p | <0.001* | <0.001* | |||

| *p<0.05 | |||||

Table 1: Distributions and comparisons of discoloration measurements by materials and groups.

For the compomer discs, the discoloration score of the control group was significantly higher than the scores of the Al discs+ spiral wheels, Al discs + felt discs, and Al discs + rubber kit groups (p < 0.001, p = 0.005, p = 0.037, respectively). Additionally, the discoloration score of the Al discs group was significantly higher than that of the Al discs + spiral wheels group (p = 0.040).

For the composite discs, significant differences in discoloration scores were found between the Al discs + spiral wheels and Al discs + rubber kit groups compared to the Al discs + felt discs and Al discs groups (p = 0.003, p < 0.001, p = 0.006, and p < 0.001, respectively). The discoloration scores of the Al discs + felt discs and Al discs groups were higher than those of the Al discs + spiral wheels and Al discs + rubber kit groups (Figure 2).

Figure 2: Changes in composite discs due to staining. (A) Before staining, (B) after staining. Specimens from five groups (n = 12) according to the polishing method: Group 1: four-step aluminum oxide discs, Group 2: aluminum oxide discs and rubber kit, Group 3: aluminum oxide discs and felt discs, Group 4: aluminum oxide discs and spiral wheels, and Group 5: no polishing. Please click here to view a larger version of this figure.

When comparing the compomer and composite discs, the discoloration of the Al discs and Al discs + felt discs treated composite discs was significantly higher than that of the compomer discs (p < 0.05). No significant differences in discoloration were found between the materials in the Al discs + rubber kit, Al discs + spiral wheels, and control groups (p > 0.05) (Figure 3).

Figure 3: Histogram of the distributions of discoloration measurements by materials and groups. Please click here to view a larger version of this figure.

According to the statistical results of this study, no significant (p < 0.05) differences were found in the color measurements of materials among the Al discs + rubber kit, Al discs + spiral wheels, and no polishing group for the nanohybrid composite and compomer (p > 0.05). This result is consistent with previous studies10,14,15. The reason for these results can be attributed to the fact that compomers have a similar chemical structure to composite resins. Based on the results of this study, significant differences in staining measurements between the materials were observed in the Al discs and Al discs + felt discs groups (p < 0.05). The staining measurements for the nanohybrid were higher than those for the compomer. This may be due to the fact that composite resins containing TEGDMA in their composition release significantly more monomers in aqueous environments compared to UDMA-based composite resins, leading to a greater change in color16. According to the study results, clinically unacceptable discoloration was observed with all polishing methods. This outcome might be influenced by the high staining effect of the cherry juice used as a staining agent in this study17.

Discussion

Achieving a successful aesthetic restoration depends on two key factors: color matching and maintaining long-term color stability. Restoration materials often suffer from surface and subsurface staining due to the increased consumption of staining foods and beverages11,18. The discoloration of polymeric materials caused by colored liquids, such as coffee, tea, juice, and other drinks, has been documented in the literature. Juice is one of the most commonly consumed beverages during childhood and poses a risk of staining2,19. In previous studies, immersion of resin composite samples in liquids such as cola, red wine, vodka, coffee, tea, orange juice, and fruit juices for 7 days resulted in significant changes in translucency as well as noticeable discoloration17,18. For this reason, juice was used as the staining agent in the study.

The colors of all samples were measured with a reflective spectrophotometer20. In this study, a spectrophotometer was utilized with the CIELab coordinate system, as reported previously1,21. The CIELab system, used to measure color change (ΔE), is commonly employed in dentistry to record color differences. The L*, a*, and b* values used in this system are evenly distributed in a perceptual color space. Although the CIEDE2000 method offers better perceptibility of color differences in dental shades, most color studies have predominantly used the CIELab method22,23.

Compomers are the most commonly used restorative materials in pediatric dentistry. They are primarily formed by combining the benefits of composite and glass ionomer cements24. It has been reported that the enhanced polish obtained with compomer is likely due to its smaller filler particles and the lack of air bubbles25. In that study, when the physical properties of eight hybrid filling materials were compared, surface roughness increased to varying degrees in all materials after abrasion. The least roughness was observed in the polyacid-modified resin composite25.

Similarly, in this study, compomer, with the lowest filler content by volume (50%), was found to have the smoothest surface among the tooth-colored materials examined. Different finishing and polishing techniques affected the color stability of compomer14. The staining values of the control group were higher than those of Al discs + spiral wheels, Al discs + felt discs, and Al discs + rubber kit groups. Consistent with these findings, previous research has demonstrated that different finishing and polishing techniques influence the color stability of restoration surfaces1,21,22.

Previous research revealed a notable relationship between the form of composite resin and the polishing procedure for color change14,26. In a previous study investigating the primary effects of finishing and polishing methods on color stability, the average values of all groups were significantly different from each other14. In this study, similarly, significant differences were found between the Al discs + spiral wheels and Al discs + rubber kit groups and the Al discs + felt discs and Al discs groups within the composite group (p = 0.003, p < 0.001, p = 0.006, and p < 0.001). However, ΔE was more than the clinically acceptable range (ΔE > 3.3) for all groups. Thus, different polishing procedures affect the color stability of restorative materials. In this study, four different finishing and polishing systems were used, with fruit juice as the coloring solution. Future research can make use of more finishing and polishing technologies, as well as various liquid and drink coloring agents. Furthermore, since this study was conducted in vitro, it was not possible to fully replicate the oral environment.

According to the study results, the selection of resin-based restorative materials with different brands or shades in future studies could significantly affect color change. Considering the cooperation level of pediatric patients and the dentist-child relationship, the most suitable polishing method should be selected. Within the limitations of this study, significant differences were found between the staining measurements of the compomer and composite materials across the groups. For the compomer group, polishing procedures reduced material discoloration. For the composite material, the least discoloration was observed in the groups Al discs + spiral wheels and Al discs + rubber kit groups. Proper finishing and polishing procedures can enhance the color stability of restorations. It is important to follow the sequence of materials in the polishing protocol according to the manufacturer's instructions and to ensure that the specimens are prepared with a smooth and standardized surface. This in vitro study will lead to future clinical studies.

Disclosures

The authors declare that they have no competing interests.

Acknowledgements

The authors express gratitude to all the participants who generously dedicated their time and took part in this research.

Materials

| Name | Company | Catalog Number | Comments |

| Compomer (A2 Shade) | UDMA, Carboxylic acid modified dimethacrylate (TCB resin), TEGDMA, Trimethacrylate resin (TMPTMA), Dimethacrylate resins, Camphorquinone, Ethyl4(dimethylamino)benzoate, Butylated hydroxy toluene (BHT), UV stabilizer, Strontium-alumino-sodium-fluoro-phosphor-silicate glass , Highly dispersed silicon dioxide, Strontium fluoride, Iron oxide pigments and titanium oxide pigments | Compomer XP, Dentsply DeTrey GmbH, Konstanz, Germany | - |

| Composite Resin (A2 Shade) | BisGMA,TEGDMA, Silica – zirconium, composite | Estelite Sigma Quick, Tokuyama, Tokyo, Japan | - |

| Dian Fong | Diamond Stone | China | One step |

| Easyshade | spectrophotometer | VITA Zahnfabrik H. Rauter GmbH & Co. KG | |

| G*Power software ver. 3.1.9.2 | Erdfelder, Faul, & Buchner | ||

| Polimax | Felt dics | TDV, Brazil | One step |

| SPSS Statistics 25 | Software | IBM , Armonk, New York, ABD | |

| Sof-Lex (S) | Aluminum oxide coated discs (coarse,medium,fine, super fine) | 3M/ESPE, MN, USA | Multi-step |

| Sof-Lex Spiral Wheels | Aluminium oxide and diamond particles impregnated in a thermoplastic elastomer | 3M/ESPE, MN, USA | Two step |

| *Bis-GMA Bisphenol-A diglycidylether methacrylate, UDMA Urethane dimethacrylate, |

References

- Jrady, A., Ragab, H., Algahtani, F. N., Osman, E. In vitro study on the impact of various polishing systems and coffee staining on the color stability of bleach-shaded resin composite. BMC Oral Health. 24 (1), 712(2024).

- Güler, A. U., Güler, E., Yücel, A. Ç, Ertaş, E. Effects of polishing procedures on color stability of composite resins. J Appl Oral Sci. 17 (2), 108-112 (2009).

- Yadav, R. D., Raisingani, D., Jindal, D., Mathur, R. A comparative analysis of different finishing and polishing devices on nanofilled, microfilled, and hybrid composite: A scanning electron microscopy and profilometric study. Int J Clin Pediat Dent. 9 (3), 201(2016).

- Craig, R. G., O'Brien, W. J., Powers, J. M. Dental materials: Properties and manipulation. , Mosby. (2004).

- Almutairi, M., et al. The effects of different pediatric drugs and brushing on the color stability of esthetic restorative materials used in pediatric dentistry: An in vitro study. Children. 9 (7), 1026(2022).

- Yu, H., et al. Effects of carbamide peroxide on the staining susceptibility of tooth-colored restorative materials. Oper Dent. 34 (1), 72-82 (2009).

- Sabatini, C., Campillo, M., Aref, J. Color stability of ten resin-based restorative materials. J Esthetic Restor Dent. 24 (3), 185-199 (2012).

- Lopes, I. aD., Monteiro, P. J. V. C., Mendes, J. J. B., Gonçalves, J. M. R., Caldeira, F. J. F. The effect of different finishing and polishing techniques on surface roughness and gloss of two nanocomposites. Saudi Dental J. 30 (3), 197-207 (2018).

- Scheibe, K. G. B. A., Almeida, K. G. B., Medeiros, I. S., Costa, J. F., Alves, C. M. C. Effect of different polishing systems on the surface roughness of microhybrid composites. J Appl Oral Sci. 17 (1), 21-26 (2009).

- Erdemir, U., Yildiz, E., Eren, M. M., Ozsoy, A., Topcu, F. T. Effects of polishing systems on the surface roughness of tooth-colored materials. J Dental Sci. 8 (2), 160-169 (2013).

- Paravina, R. D., Roeder, L., Lu, H., Vogel, K., Powers, J. M. Effect of finishing and polishing procedures on surface roughness, gloss and color of resin-based composites. Am J Dentistry. 17 (4), 262-266 (2004).

- Yildiz, E., Karaarslan, E. S., Simsek, M., Ozsevik, A. S., Usumez, A. Color stability and surface roughness of polished anterior restorative materials. Dental Mater J. 34 (5), 629-639 (2015).

- Farah, R. I., Elwi, H. Spectrophotometric evaluation of color changes of bleach-shade resin-based composites after staining and bleaching. J Contemp Dent Pract. 15 (5), 587-594 (2014).

- Ülker, Ö, Yılmaz, F. Evaluation of the effect of different finishing and polishing systems on surface roughness and color stability of different restorative materials. Journal of International Dental Sciences. 7 (2), 16-26 (2021).

- Yap, A. U., Yap, S., Teo, C., Ng, J. Finishing/polishing of composite and compomer restoratives: Effectiveness of one-step systems. Oper Dent. 29 (3), 275-279 (2004).

- Pires-De, F. D. C. P., Garcia, L. D. F. R., Roselino, L. D. M. R., Naves, L. Z. Color stability of silorane-based composites submitted to accelerated artificial ageing-an in situ study. J Dent. 39, e18-e24 (2011).

- Yikilgan, I., et al. The effects of fresh detox juices on color stability and roughness of resin-based composites. J Prosthodont. 28 (1), e82-e88 (2019).

- Fontes, S. T., Fernández, M. R., Moura, C. M. D., Meireles, S. S. Color stability of a nanofill composite: Effect of different immersion media. J Appl Oral Sci. 17 (5), 388-391 (2009).

- Tan, B., Yap, A., Ma, H., Chew, J., Tan, W. Effect of beverages on color and translucency of new tooth-colored restoratives. Oper Dent. 40 (2), E56-E65 (2015).

- Okubo, S. R., Kanawati, A., Richards, M. W., Childressd, S. Evaluation of visual and instrument shade matching. J Prosthet Dent. 80 (6), 642-648 (1998).

- Gönülol, N., Yılmaz, F. The effects of finishing and polishing techniques on surface roughness and color stability of nanocomposites. J Dent. 40 (Suppl 2), e64-e70 (2012).

- Paolone, G., et al. Color stability of resin-based composites: Staining procedures with liquids-a narrative review. J Esthet Restor Dent. 34 (6), 865-887 (2022).

- Schmitt, V. L., et al. Polishing techniques effect on microhybrid, nanohybrid and nanofilled composites color and surface roughness stability. Bioscience J. 32 (1), 262-271 (2016).

- Ruse, N. D. What is a "compomer". J Can Dent Assoc. 65 (9), 500-504 (1999).

- Gladys, S., Van Meerbeek, B., Braem, M., Lambrechts, P., Vanherle, G. Comparative physico-mechanical characterization of new hybrid restorative materials with conventional glass-ionomer and resin composite restorative materials. J Dent Res. 76 (4), 883-894 (1997).

- Abo-Eldahab, G., Kamel, M. Color stability of nanofilled and suprananofilled resin composites with different polishing techniques after immersion in coffee solution. Egyptian Dental Journal. 69 (1), 827-836 (2023).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved